Upcycling plastic bottles into vanilla flavoring

Baking is one of my favorite pastimes. There is just something so soothing and stress relieving about carefully measuring each ingredient, mixing them together, and ending up with a delicious cake, loaf of bread or batch of cookies.

Given my love of baking, I am always keeping tabs on the continually escalating price of pure vanilla extract. This past Christmas my family gifted me a 16-ounce bottle of pure vanilla extract with an eye-popping $80 price tag. Authentic pure vanilla extract is made from soaking vanilla pods in alcohol, which releases about 250 taste and aroma components from the pod.

Given my love of baking, I am always keeping tabs on the continually escalating price of pure vanilla extract. This past Christmas my family gifted me a 16-ounce bottle of pure vanilla extract with an eye-popping $80 price tag. Authentic pure vanilla extract is made from soaking vanilla pods in alcohol, which releases about 250 taste and aroma components from the pod.

Vanillin is the primary component of extracted vanilla beans that is responsible for the characteristic vanilla smell and taste. This molecule is in high demand in the food, cosmetic, and herbicide industries (yes, you read that correctly – vanillin is often used in the production of weed killers). Because pure vanilla extract takes a lot of labor and land to produce, manufacturers have found ways to synthesize vanillin from other sources like wood tar or lignin from woody plants to keep up with the high demand for vanilla flavoring.

Unfortunately, these synthesis processes use fossil fuel inputs and create a significant amount of pollution. Scientists recently found a way to make synthetic vanilla flavoring from used plastic products, eliminating the need for fossil fuels while also recycling single use plastics that plague our earth.

The global plastic waste crisis

We live in a world filled with plastic, from the cell phone or computer you are reading Shareable Science on right now to the toothbrush you used to brush your teeth this morning to the plastic containers keeping your food fresh. The first man-made plastic was invented in the mid-1800’s as a substitute for ivory which was in high-demand in the newly popular billiards scene.

In the century and a half since the advent of plastics, they have helped save lives with disposable plastic syringes, artificial organs, and life-saving devices, made space travel possible, and cut down on food-related bacteria by providing superior packaging. However, the conveniences that plastics afforded us led to a throw-away culture that has fueled a global plastic waste crisis.

In the century and a half since the advent of plastics, they have helped save lives with disposable plastic syringes, artificial organs, and life-saving devices, made space travel possible, and cut down on food-related bacteria by providing superior packaging. However, the conveniences that plastics afforded us led to a throw-away culture that has fueled a global plastic waste crisis.

Single-use plastics account for 40 percent of the plastic produced each year. The recycling rate of plastic is extremely low and most plastics still end up in landfills or in the environment, where they take centuries to decompose. About 10 percent of the world’s discarded plastic eventually ends up in our oceans. Millions of land and marine animals are killed by plastics each year due mainly to entanglement and starvation.

Because plastic is continually breaking down in the ocean into smaller pieces called microplastics, it is nearly impossible to retrieve it once it has made it into the water supply. Microplastics themselves are an environmental problem, having been found in the deepest parts of the oceans and in human food and water supplies around the world.

How do scientists turn plastic into vanilla?

In order to combat the growing environmental problem of global plastic waste, scientists have begun to pursue alternative methods for recycling plastics. Most of the current methods degrade plastic and use the resulting base molecules to create more plastic materials.

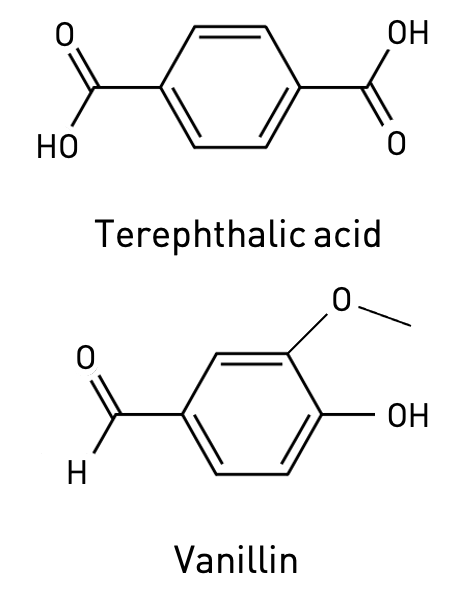

Scientists from the University of Edinburgh discovered a way to reap more value from the plastic recycling process by turning post-consumer plastic into synthetic vanilla flavoring. To do this, they used genetically engineered E. coli bacteria that have previously been used for the synthesis of vanilla from glucose. The bacteria were shown to convert terephthalic acid (a molecule derived from a type of plastic called PET) into the high value compound vanillin.

You are probably thinking this is some crazy science fiction story because there is no way that a bacteria like E. coli can just magically transform a plastic bottle into vanilla flavoring, right? It turns out that the transformation is possible thanks to a little bit of chemistry.

As you can see in the image to the right, terephthalic acid and vanillin molecules look structurally similar. The genetically modified E. coli makes a few changes to the number of hydrogen and oxygen atoms bonded to the terephthalic acid’s carbon ring, the circular structure in the center of the molecule. These chemical adjustments create vanillin.

Further testing is needed to confirm the vanillin produced in this way is suitable for making fragrances and flavorings. The entire process also has to be successfully scaled to produce liters of vanillin. If that hurdle can be overcome, we’ll have a more environmentally friendly process to create this high-demand product. And perhaps one day bottle-based vanillin will appear in my Christmas stocking.

To schedule a media interview with Dr. Neil Lamb or to invite him to speak at an event or conference, please contact Lara Burhenn by email at lburhenn@hudsonalpha.org or by phone: Office (256) 327-5216 | Cell (256) 937-8210