An Everyday DNA blog article

Written by: Sarah Sharman, PhD, Science writer

Illustrated by: Cathleen Shaw

Although most people probably trace rubber’s first uses to 19th-century Europe and the Industrial Revolution, its origins span thousands of years to Mexico and Central America. As far back as 1600 BC, MesoAmerican people used liquid rubber for medicines, rituals, and paint. Ancient peoples also made recreational balls from rubber. Indigenous people and Spanish settlers in South America waterproofed their shoes, clothing, and hats by dipping cloth into latex.

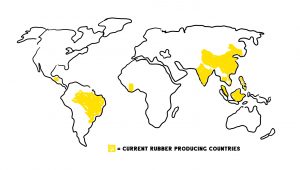

Today, however, about 70 percent of the global rubber industry is focused on automobile and plane tires. The remaining rubber is used for other goods like medical gloves, sporting gear, shoes, and clothing. It might be a surprise that nearly all the world’s natural rubber comes from one plant source grown almost exclusively in Asia. Let’s learn more about the history of rubber, the rubber tree monopoly, and the quest for alternative sources of natural rubber.

What is natural rubber?

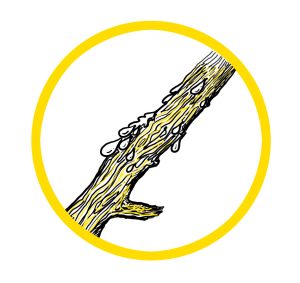

Natural rubber is made from latex, a milky liquid found in the latex ducts or cells of rubber-producing plants. Around 20,000 species of plants produce latex, but only about 2,500 species contain rubber in their latex. Today, about 99 percent of our natural rubber comes from the Hevea brasiliensis tree (rubber tree), native to South America. In 1734, a French explorer discovered the rubber-producing trees during a trip to South America.

Rubber trees have interconnected latex tubes in their trunks that form a network of latex transport. When the trunk is cut with a special incision, the tree bleeds latex that can be collected into buckets like maple syrup and turned into rubber products. In its native state, latex becomes sticky in response to warm weather and hardens and cracks in cold weather. Rubber is only one component of natural latex. Other processing steps are required to create quality rubber with long-lasting properties.

Rubber trees have interconnected latex tubes in their trunks that form a network of latex transport. When the trunk is cut with a special incision, the tree bleeds latex that can be collected into buckets like maple syrup and turned into rubber products. In its native state, latex becomes sticky in response to warm weather and hardens and cracks in cold weather. Rubber is only one component of natural latex. Other processing steps are required to create quality rubber with long-lasting properties.

In 1839, Charles Goodyear discovered that the properties of rubber could be improved through a process called vulcanization, wherein the rubber is heated with a small percentage of sulfur. The resulting rubber has improved elasticity, resilience, hardness, and weather resistance. In 1888, Dunlop invented the air-filled rubber tire, making rubber an extremely important raw material worldwide.

During the late 1800s/early 1900s, the Brazilian Amazon was the only source of rubber in the world. It controlled the price and export of rubber, making it an expensive commodity. In 1876, a British explorer smuggled 70,000 rubber seeds from Brazil to England. The seeds that survived the overseas journey were sent to Malaysia, where they were planted to start the first rubber plantations in Asia. Nowadays, around 90 percent of natural rubber is produced in Asia. Thailand and Indonesia alone supply more than 60 percent of the world’s natural rubber.

As the demand for rubber grew, scientists began engineering synthetic substitutes for natural rubber. Synthetic rubber is produced through a chemical process that generally involves crude oil. The production of synthetic rubber quickly rose at the end of World War II because the Asian rubber supply was cut off, leading the US, Germany, and Russia to search for alternative rubber sources.

As the demand for rubber grew, scientists began engineering synthetic substitutes for natural rubber. Synthetic rubber is produced through a chemical process that generally involves crude oil. The production of synthetic rubber quickly rose at the end of World War II because the Asian rubber supply was cut off, leading the US, Germany, and Russia to search for alternative rubber sources.

Synthetic rubber does not have all the properties of natural rubber. For example, it does not have the strength of natural rubber, which is critical for high-stress tires for trucks, aircraft, and racing cars. Natural rubber cannot be replaced by synthetic rubber in most applications, making it a commodity of such global importance that it is included on some countries’ critical raw materials lists.

The search for an alternative source of natural rubber

Sourcing rubber from a singular region of the globe is akin to putting all of one’s eggs in one basket. Should the basket break or be stolen, you will no longer have eggs for breakfast. Similarly, if Asian producers can’t produce enough rubber, or if we are cut off from that market (like during WWII), rubber stocks would be insufficient for the world’s demand for rubber.

Several environmental factors threaten rubber tree plantations and rubber supply. Rubber trees are vulnerable to some diseases, and since Asian rubber plantations started from only a handful of seeds, all the trees are genetically similar. If one tree becomes sick, the illness can spread to the entire plantation. Rising temperatures, drought, and heavy rain affect rubber yield and, in extreme cases, kill rubber trees. This is detrimental to the livelihood of rubber farmers and the rubber industry.

Latex in the rubber from rubber trees causes severe allergic reactions in some people. Finding an alternative source of rubber that does not contain latex could mitigate the possibility of latex allergies from rubber products.

The hunt for alternative rubber sources has heightened in light of these factors. Although there are thousands of rubber-containing plants, not all produce good-quality rubber. Some plants that have been considered as alternative rubber sources are guayule, Russian dandelion, rubber rabbitbrush, goldenrod, sunflower, fig tree, and lettuce.

Guayule, a small desert shrub with big potential

Parthenium argentatum (common name- guayule (pronounced why-yoo-lee)), a perennial shrub that grows in arid regions from central Mexico to southern Texas, has more of a storied past than other alternative rubber sources. The first recorded use of guayule was in the 1500s when Spanish conquistadors found Aztecs playing with rubber balls made from the chewed plant.

Parthenium argentatum (common name- guayule (pronounced why-yoo-lee)), a perennial shrub that grows in arid regions from central Mexico to southern Texas, has more of a storied past than other alternative rubber sources. The first recorded use of guayule was in the 1500s when Spanish conquistadors found Aztecs playing with rubber balls made from the chewed plant.

In the early 1900s, a group of American industrialists, including John D. Rockefeller, invested millions of dollars in a guayule firm. By 1910, about half of all US rubber was extracted from wild guayule. Unfortunately, guayule’s success was short-lived. Poor farming methods and revolutions in Mexico contributed to the industry’s downfall.

It wasn’t until World War II that guayule saw a resurgence in interest from the government. On March 5, 1942, after Japan seized Asian rubber plantations, Congress passed the Emergency Rubber Act to meet the critical need for rubber for many wartime products. The resulting research effort, called the Emergency Rubber Project, brought together thousands of scientists and laborers, gave them over 32,000 acres of guayule, and asked them to investigate its potential as a natural source of rubber. The government-funded guayule projects ceased after the war ended. However, many researchers continued their efforts to develop guayule rubber as an alternative natural rubber source.

Guayule is an attractive candidate as a natural rubber source for several reasons. The rubber produced from guayule latex has similar qualities to the rubber from H. brasiliensis trees. Guayule is also a multi-use commodity crop. It accumulates high levels of resins with commercial application and is an ideal feedstock for biofuel generation.

How is science helping create better guayule?

It sounds like guayule is the perfect natural alternative to rubber trees, right? Guayule has great potential, but wild guayule only produces between 3 to 7 percent rubber by mass. The plants need to produce a higher percentage of rubber so the crop is economically viable. Today, the quest to develop guayule as an alternative source of rubber has two things going for it that past endeavors did not: our robust agricultural genetics field and an industrial company driving commercialization. Bridgestone is exploring guayule as a commercial business, set to begin operation in Arizona by late 2027.

Plants are made up of cells that contain DNA, a molecule that codes the proteins that help plants develop, grow, and function. DNA is also responsible for traits that distinguish one plant from another. Changes in DNA, which can occur randomly or be induced through environmental factors like radiation, sometimes confer beneficial advantages to the plant. By understanding a plant’s DNA code, scientists can determine ways to breed plants together to create new plants with desirable traits.

Plants are made up of cells that contain DNA, a molecule that codes the proteins that help plants develop, grow, and function. DNA is also responsible for traits that distinguish one plant from another. Changes in DNA, which can occur randomly or be induced through environmental factors like radiation, sometimes confer beneficial advantages to the plant. By understanding a plant’s DNA code, scientists can determine ways to breed plants together to create new plants with desirable traits.

In the case of guayule, scientists are hoping to use genetics to develop new types of guayule that produce more latex, grow faster, survive a wider climate range, and more. Before scientists can identify the pieces of DNA that confer specific traits in guayule, they must know what the guayule genome looks like in the first place. Scientists at the HudsonAlpha Institute for Biotechnology Genome Sequencing Center (GSC) are experts at sequencing complex plant genomes. Working with the DOE Joint Genome Institute (JGI), they are providing their genomic sequencing and analysis expertise to a collaborative team developing the new guayule varieties. As part of a JGI Community Science Program project led by Andrew Nelson’s lab at the Boyce Thompson Institute, the GSC team will create reference genomes representing examples of a set of chromosomes for the guayule species.

The high-quality reference genomes will open opportunities to explore genome-directed breeding, gene editing, and transgenics in guayule to create a more economically viable guayule plant. Nelson’s lab is interested in gaining a better understanding of the rubber biosynthesis pathway in guayule, particularly its response to temperature. This type of information will help scientists better modulate rubber production in guayule. By comparing the reference genome to genetic information from plants grown under different temperatures, Nelson’s lab hopes to pinpoint regions of the genome that are changed (activated or turned off) in response to temperature changes.

Other members of the project to sequence guayule’s genome include the University of Arizona, Colorado State University, and Bridgestone Americas.